Copyright © Shanghai Chuangdaozhihe Equipment Technology Co., Ltd. All Rights Reserved. Site Map

- +86-150264808540086-021-66532769 ext. 805

- chdvip888@outlook.com

- Room 711, Enterprise Plaza, 228 Meiyuan Road, Jing'an District, Shanghai, China

Waste and inefficiency are urgent problems that workshop managers need to solve. Today I will introduce a case study of a lean production line. I hope that friends in industrial engineering can understand this management method and integrate it into their own work.

Ⅰ. Lean production line concept

The lean production line, also known as the lean cell line, flexible production line, and 3.0 cell line, is a production method that uses waste-free and uninterrupted operation processes rather than batching and queuing.

Lean production lines are a management philosophy derived from the Toyota Production System. Lean is best known for its focus on reducing Toyota's seven wastes to increase overall customer value, but there's no consensus on the best way to achieve this.

Toyota Motor Corporation has grown steadily from a small company to become the world's largest automaker by focusing on how to achieve this goal.

Ⅱ. Five steps to convert a lean production line

1. Single-piece flow

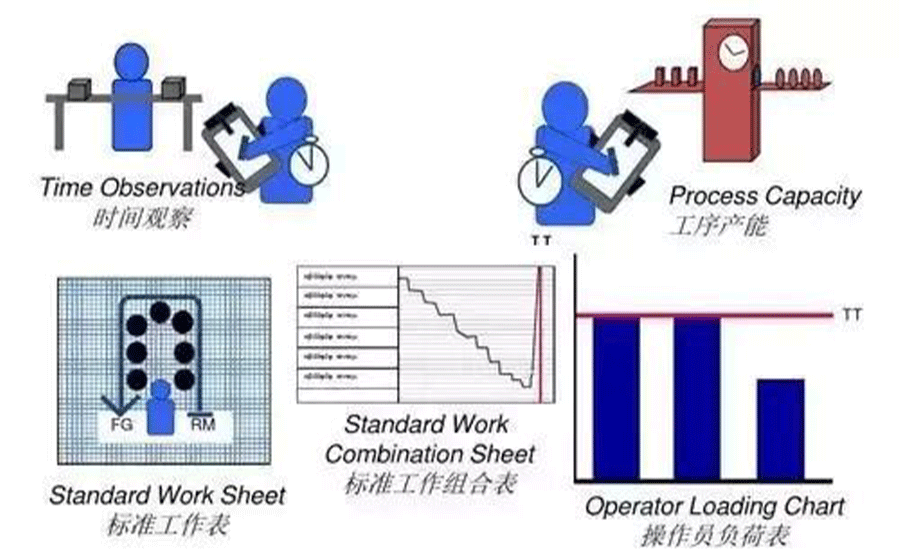

2. Standardized operations

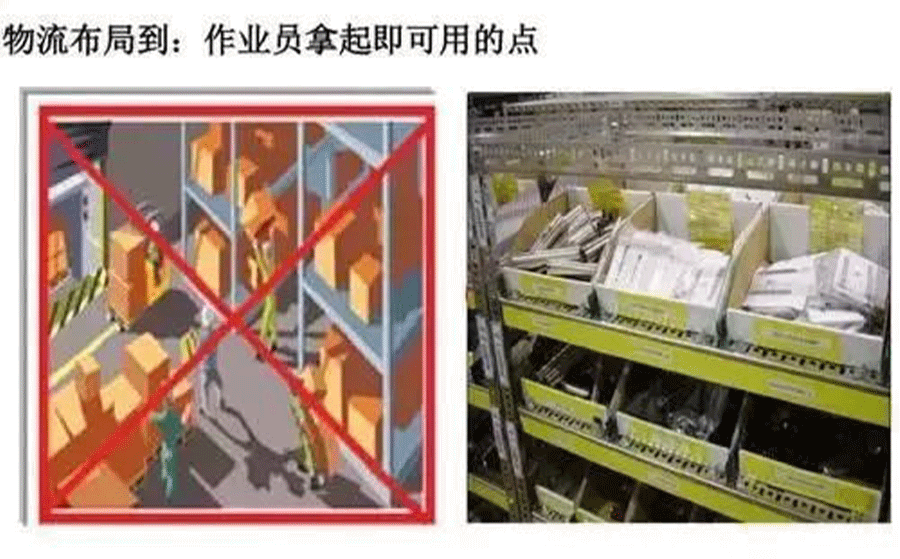

3. Materials are moved to the point of use

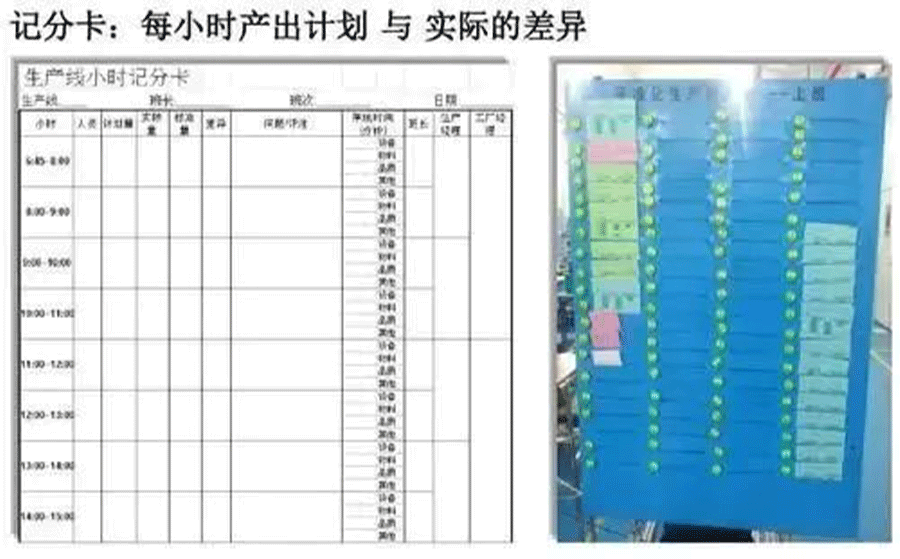

4. Hourly Output Scorecard

Ⅲ. Lean production line design principles

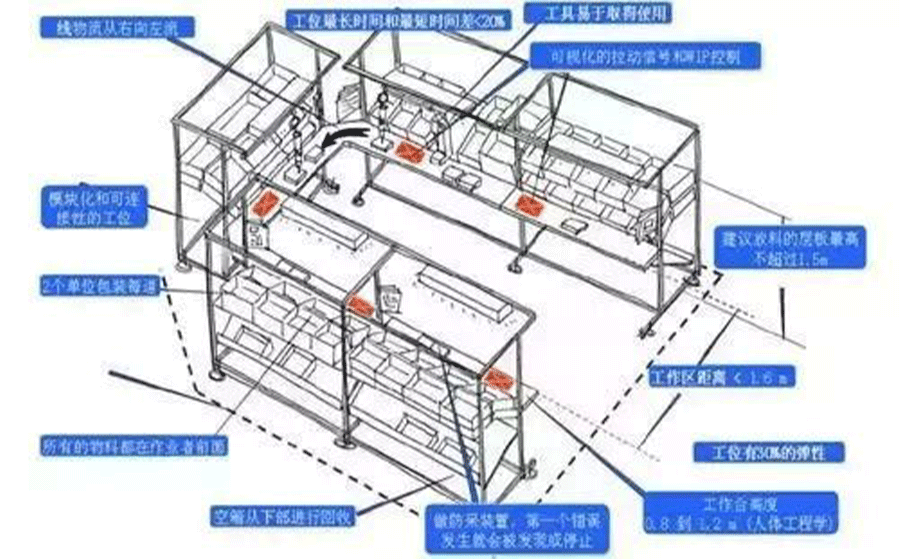

A lean production line should be designed based on specific customer needs, incorporating lean thinking and methodologies to create lean workstations and production lines. From the outset, the clear goal is to eliminate or externalize waste within the production line, maximizing efficiency. A lean production line results in less waste, greater flexibility, a more balanced process, and a more streamlined product flow.

Lean production line design is implemented in the following 9 steps:

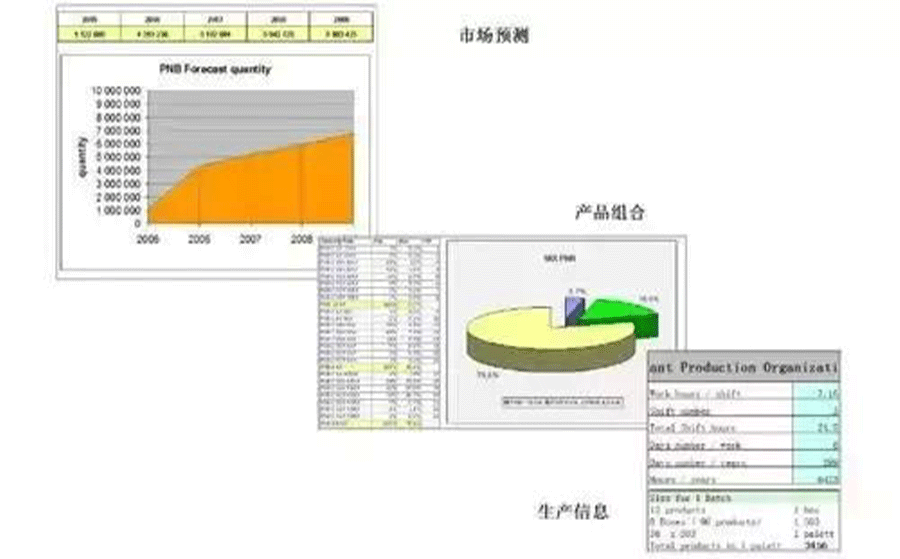

1. Demand forecast analysis

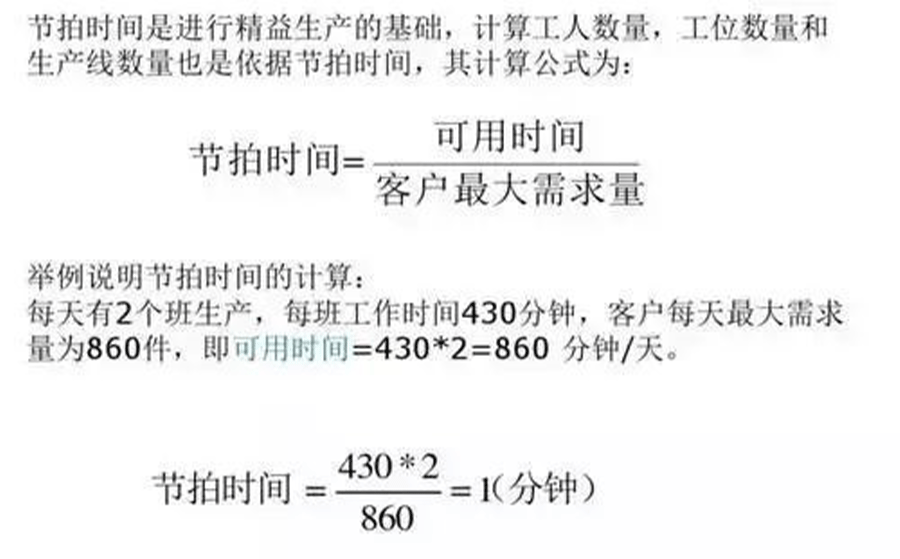

2. Takt time calculation

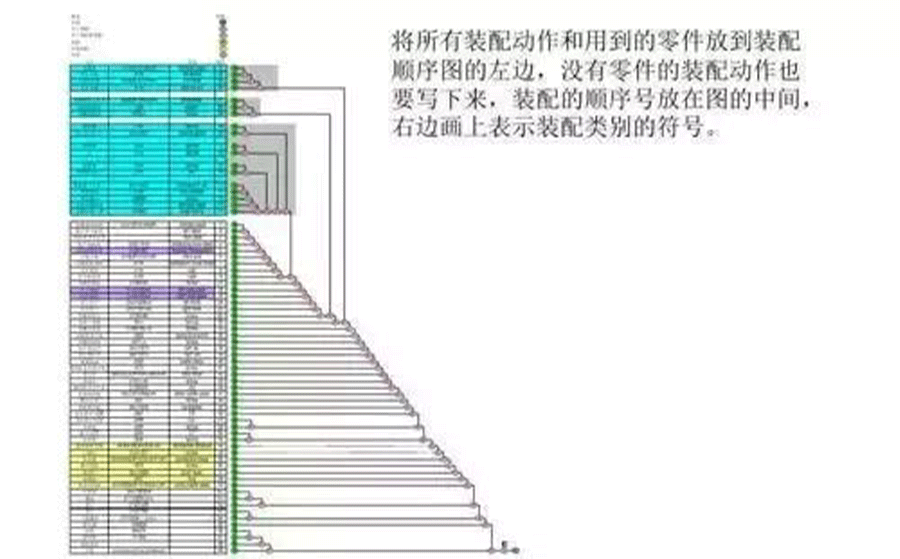

3. Assembly sequence definition

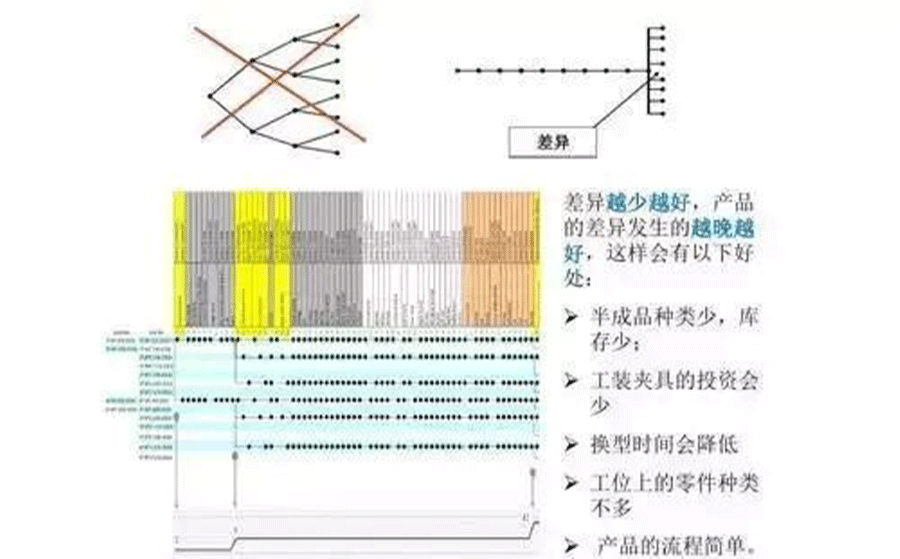

4. Differentiation Analysis

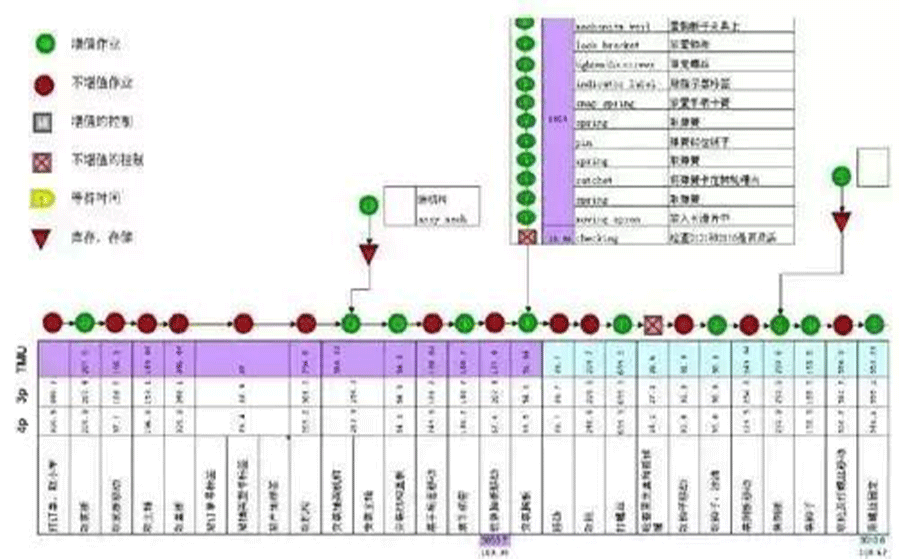

5. Work Measurement

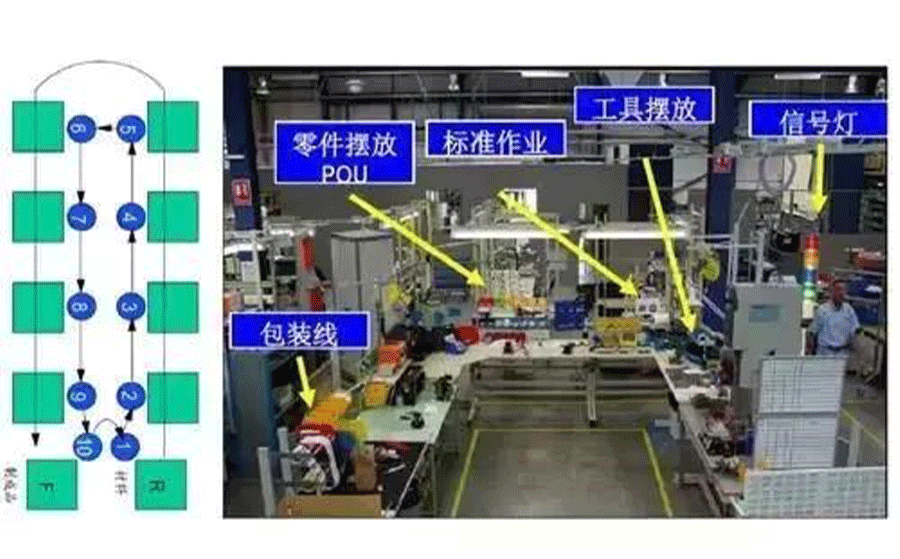

6. Line layout

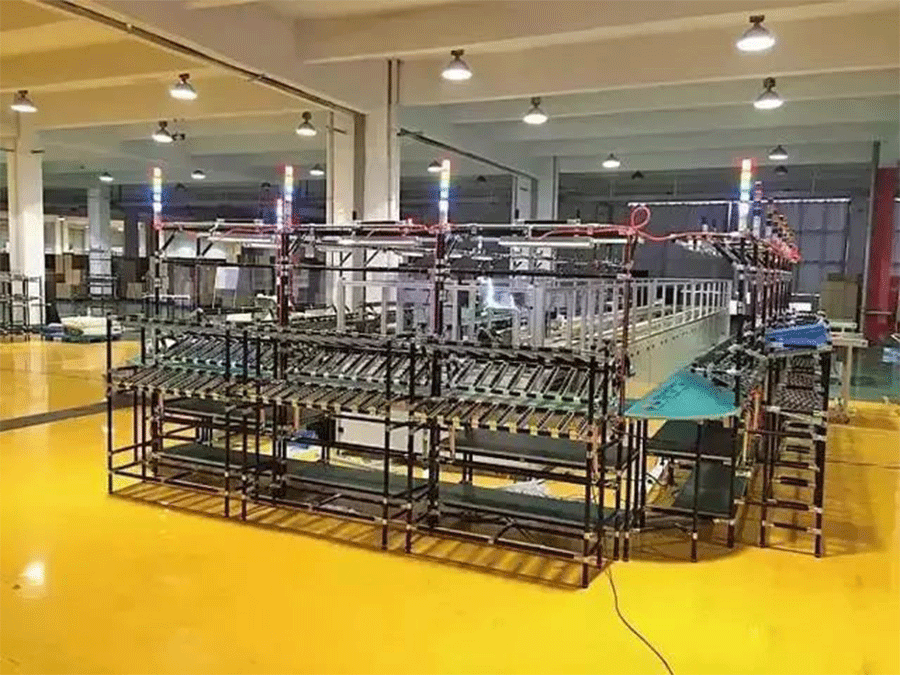

Ⅳ. Lean Production Line Case

Ten Tools to Learn Lean Production by Looking at Pictures

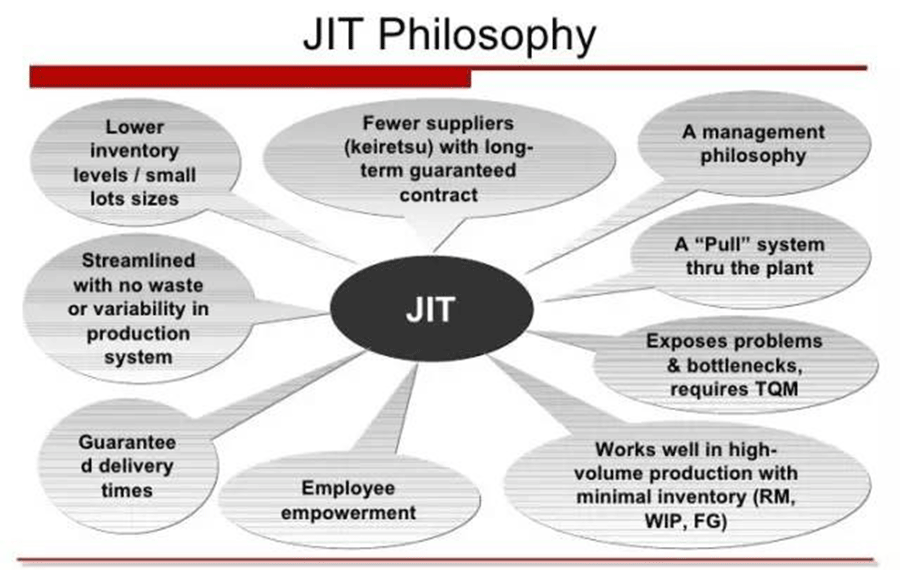

1. Just-in-Time (JIT)

The just-in-time production method originated from Toyota Motor Corporation in Japan. Its basic concept is to "produce what is needed only when it is needed, in the quantity needed." The core of this production method is to pursue a production system with no inventory, or a production system that minimizes inventory.

During production operations, we must strictly follow the standard requirements, produce according to demand, and deliver as much material as needed on site to prevent inventory abnormalities.

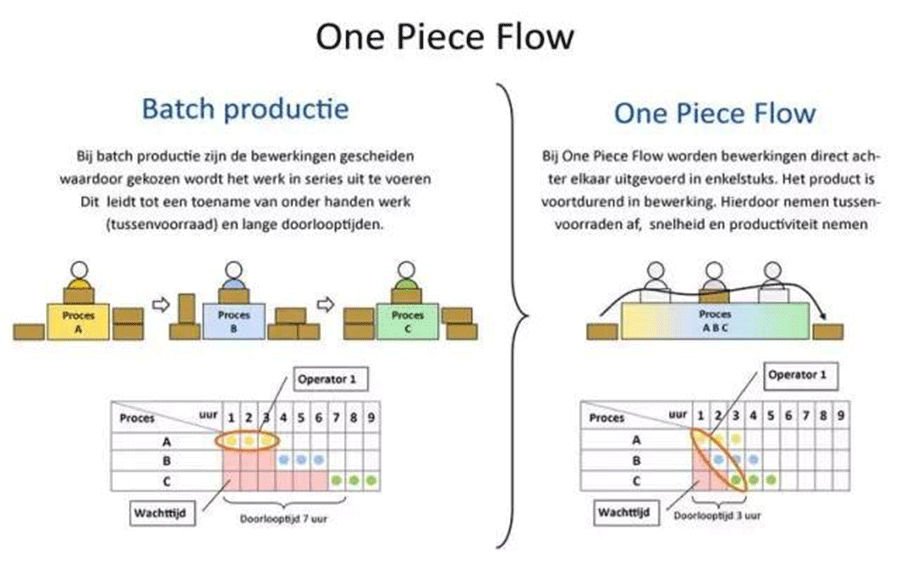

2. Single-piece flow

JIT is the ultimate goal of lean production, achieved through continuous elimination of waste, reduction of inventory, reduction of defects, and shortening of manufacturing cycle time. One-piece flow is one of the key techniques that helps us achieve this goal.

3. Kanban

Kanban boards are a means of communicating production management information within a factory. Kanban cards contain a considerable amount of information and can be reused repeatedly. There are two common types of kanban boards: production kanbans and shipping kanbans. Kanban boards are straightforward, easily visible, and easy to manage.

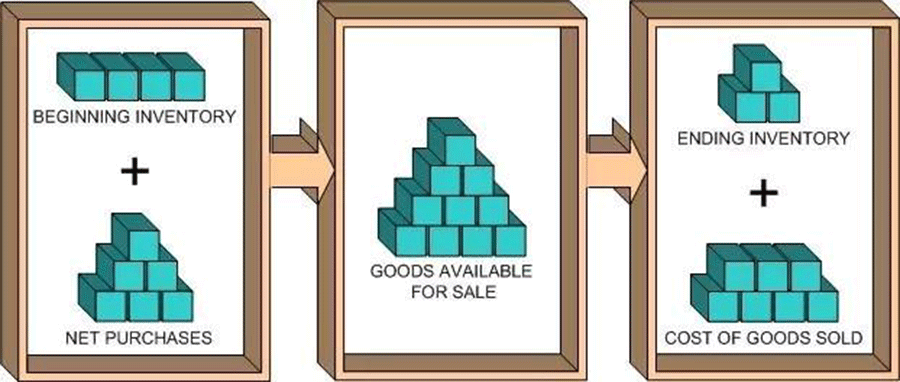

4. Zero inventory management

Factory inventory management is a fundamental component of the supply chain. In the manufacturing industry, strengthening inventory management can shorten and eventually eliminate the storage time of raw materials, semi-finished products, and finished products, reduce inefficient operations and waiting times, prevent stockouts, and improve customer satisfaction across the three key factors of quality, cost, and delivery. Excessive inventory wilting can cause difficulties during inventory checks, so we need to match inventory to demand.

5. Total Productive Maintenance (TPM)

Through full employee participation, we create well-designed equipment systems, improve the utilization of existing equipment, achieve safety and quality, and prevent failures, thereby reducing costs and improving overall production efficiency. This not only embodies 5S, but more importantly, it also includes work safety analysis and safe production management.

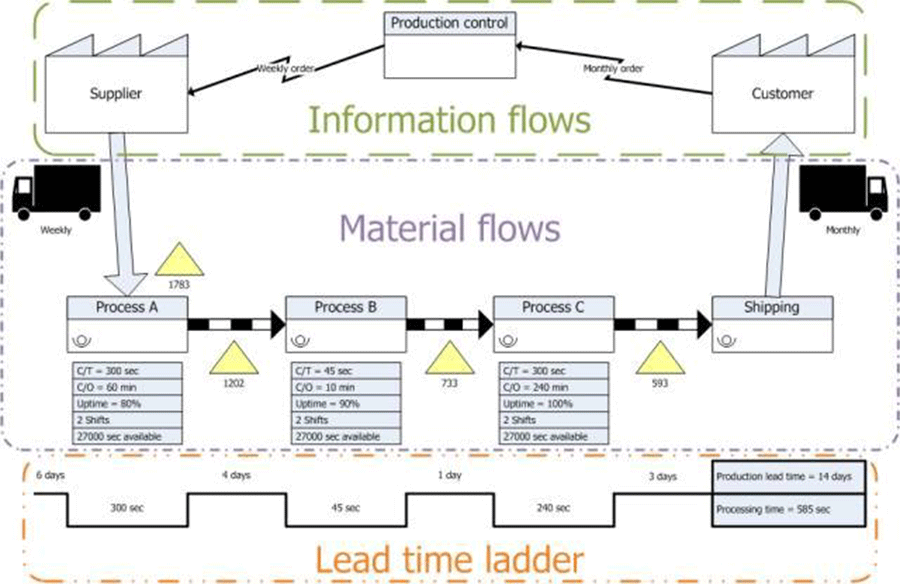

6. Use value stream mapping to identify waste

The production process is rife with alarming waste. Value Stream Mapping is the foundation and key to implementing lean systems and eliminating process waste. It uses data to clearly show the relationship between waste and benefits.

7. Production line balance design

Irrational assembly line layouts cause unnecessary movement of workers, reducing production efficiency. Inappropriate movement arrangements and process routings cause workers to repeatedly pick up and put down workpieces. Assessments are crucial, as is on-site planning. Saving time and effort is paramount. Achieving twice the result with half the effort is key.

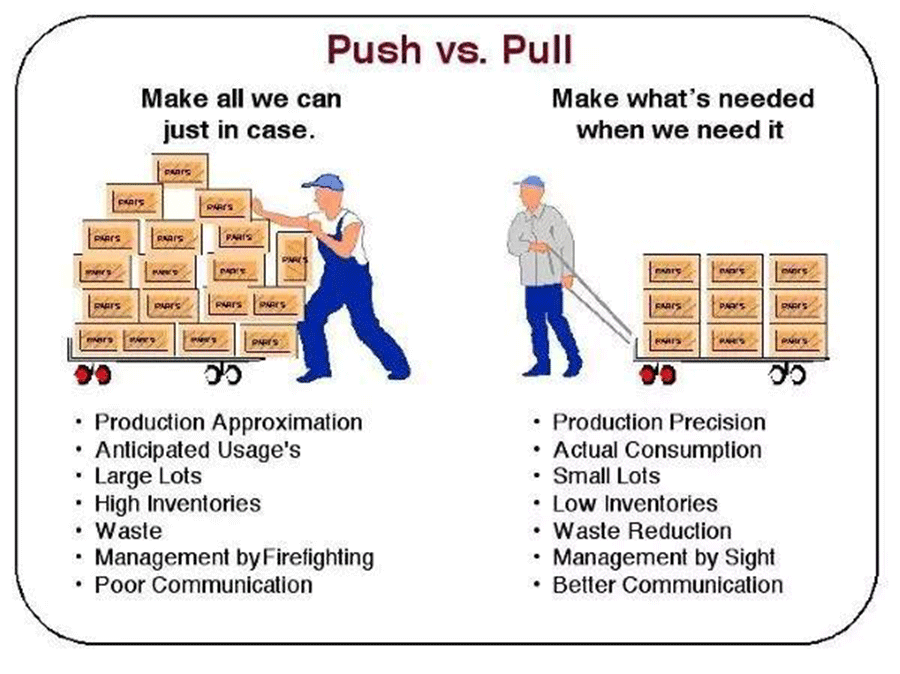

8. Pull system and supplementary pull system

Pull production uses kanban management as a tool, employing a "take-and-place system." This means that downstream processes produce based on market demand. Any shortage of work-in-process (WIP) in this process is taken from upstream processes, creating a pull control system throughout the entire process. Never produce more than one product. Just-in-time (JIT) relies on pull production as its foundation, and pull-system operations are a hallmark of lean production. The zero inventory pursued by lean production is primarily achieved through pull-system operations.

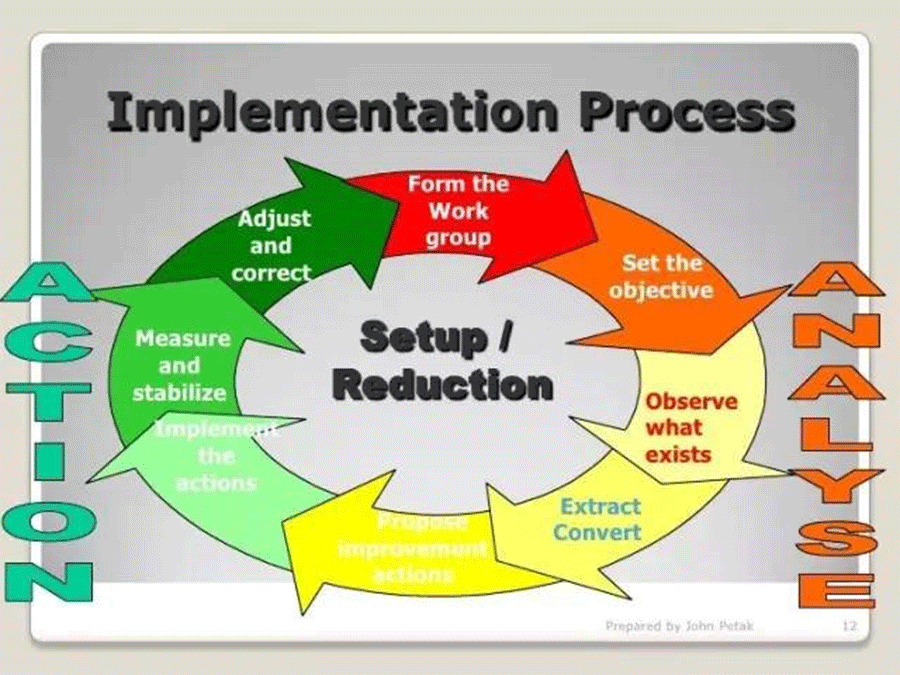

9. Reduce setup time (SetupReduction)

To minimize waste from line downtime, the process of reducing setup time involves gradually removing and reducing all non-value-added activities and transforming them into processes that can be completed without line downtime. Lean manufacturing is achieved through the continuous elimination of waste, reduction of inventory, reduction of defects, and shortening of manufacturing cycle times. Reducing setup time is one of the key techniques that helps us achieve these goals.

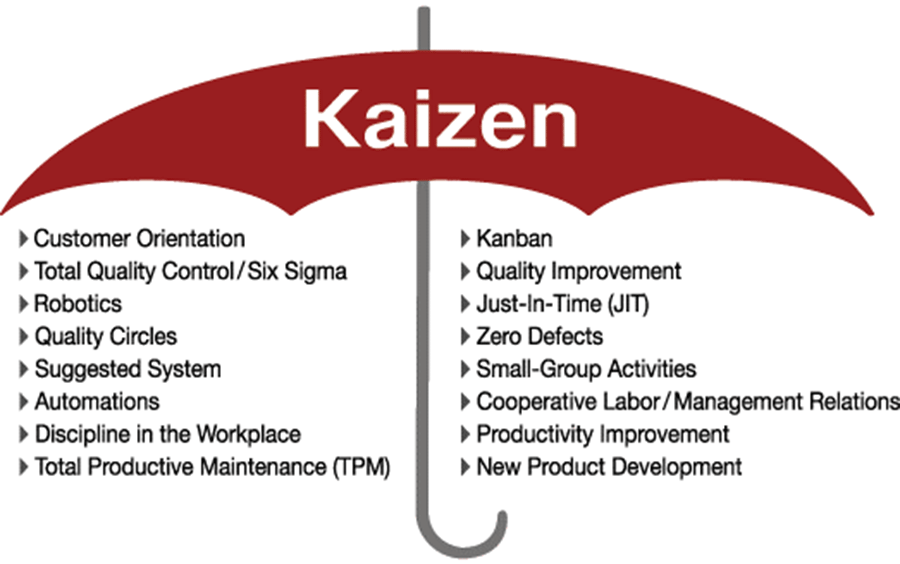

10. Kaizen

The magic begins to happen when you begin to precisely define value, identify the value stream, align the steps that create value for a specific product, and enable customers to pull value from the enterprise.