Copyright © Shanghai Chuangdaozhihe Equipment Technology Co., Ltd. All Rights Reserved. Site Map

- +86-150264808540086-021-66532769 ext. 805

- chdvip888@outlook.com

- Room 711, Enterprise Plaza, 228 Meiyuan Road, Jing'an District, Shanghai, China

Hello, everyone , welcome to Chuangdao Information

AGV is widely used in warehousing and flexible production lines . In order to enable AGV to operate more safely in complex environments, obstacle avoidance function is essential.

Obstacle avoidance refers to the process in which the AGV senses static or dynamic obstacles on its route through sensors during its movement, and implements emergency braking or bypasses the obstacles.

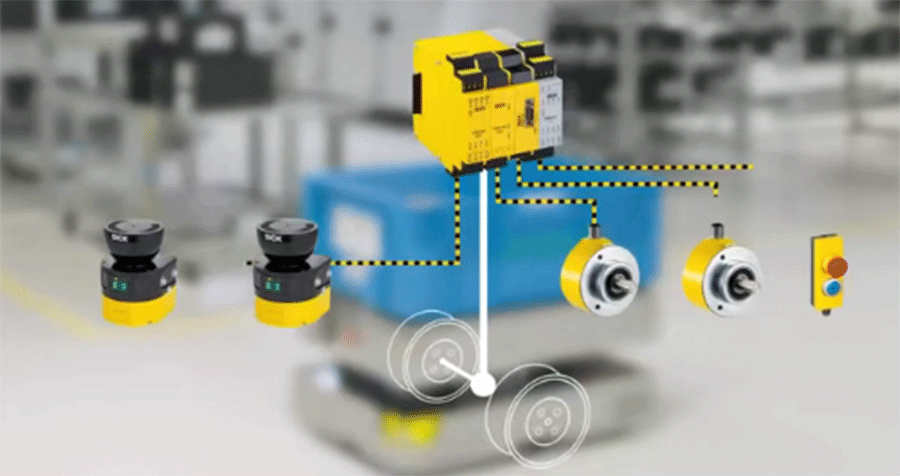

AGV obstacle avoidance systems can be divided into two categories: one is contact sensors, such as installing a mechanical anti-collision structure in front of the AGV. When it contacts an obstacle, the AGV will brake and stop for protection , the other is non-contact sensors, such as ultrasonic, infrared , and laser sensors ( as shown in Figure 1 ) . Through these sensors , the AGV can obtain real-time information about the surrounding environment , thereby identifying information such as the size and location of obstacles.

Figure 1

The following is a brief introduction to the basic working principles of these sensors.

Ultrasonic sensor

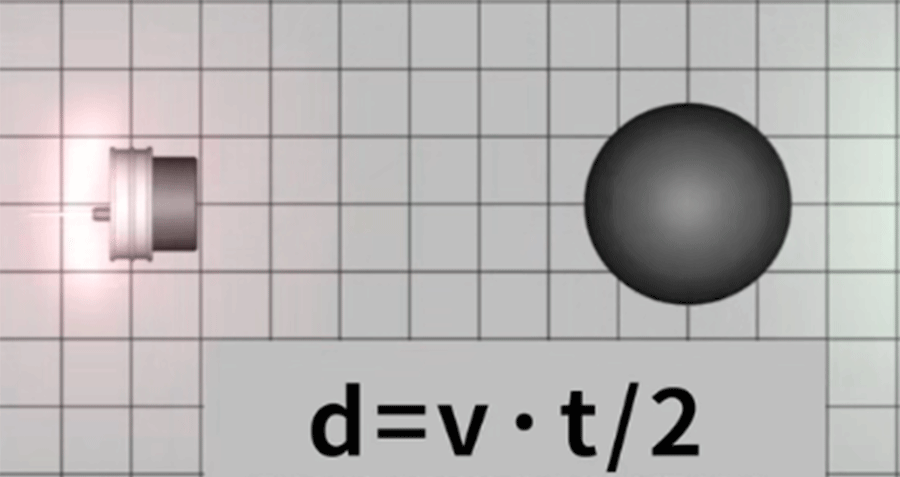

ultrasonic sensors is to measure the time of flight of ultrasonic waves and then measure distance by converting the speed of sound into the time it takes for the sound wave to reflect ( Figure 2 ) . Ultrasonic sensors are low-cost, simple to implement, and mature in technology , making them a common sensor used in AGV robots . However, ultrasonic sensors also have some drawbacks. First , they have a short operating range of only a few meters and are susceptible to environmental factors such as temperature and wind speed . Different materials also reflect and absorb sound waves differently , all of which need to be considered in practical applications.

Figure 2

Infrared sensor

Common infrared sensors use the principle of triangulation , where an infrared transmitter emits an infrared beam at a certain angle. A detector receives the emitted light and calculates the distance to an object using the geometric triangulation relationship within its structure ( see figure 3 ) . The advantages of infrared sensors are that they are unaffected by visible light , have high sensitivity, are simple in structure, are inexpensive, and can quickly detect the presence of an object . However , their measurement distance is generally short, shorter than that of ultrasonic waves, and they cannot detect the distance of transparent or nearly black objects .

Figure 3

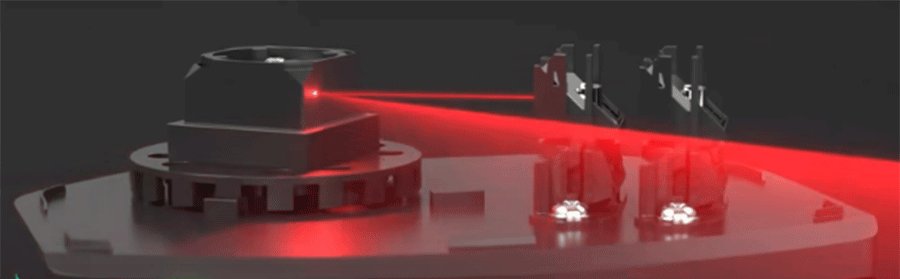

Laser sensor

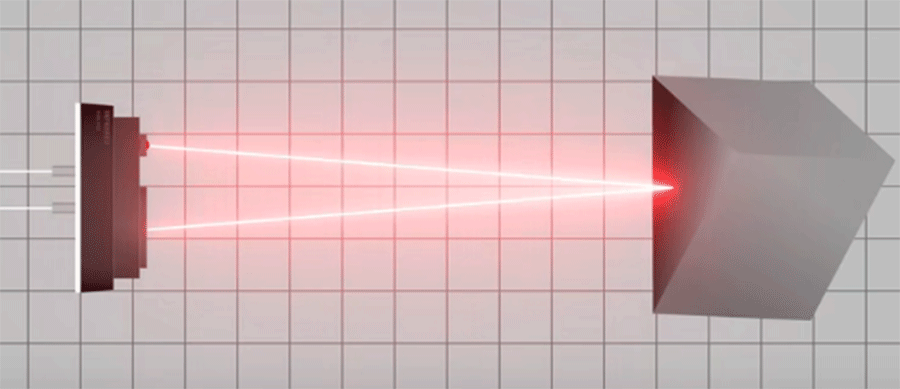

Common laser sensors are based on the Time of Flight (TOF ) principle , measuring distance by converting the laser's time of flight ( see Figure 4 ) . Similar to the ultrasonic ranging method mentioned above, laser light is emitted from a transmitter , which then strikes the target , producing an echo that is picked up by a receiver . Methods include pulsed lasers , frequency-modulated continuous lasers, and phase-shift measurement of reflected light . Laser sensors can measure distances of tens or even hundreds of meters with high accuracy . However , like infrared sensors, they cannot detect transparent objects , and their accuracy for black objects is also average. Furthermore, due to their complex structure and high component costs, laser sensors are also expensive.

Figure 4

Vision Sensor

There are many commonly used computer vision solutions, such as time-of-flight (TOF)-based depth cameras, structured light-based depth cameras, and binocular vision. The operating principle of TOF depth cameras is similar to that of laser sensors (see Figure 5). Both measure distance by calculating the time of flight of a laser beam. The difference is that laser sensors scan point by point, while TOF cameras simultaneously obtain depth information for the entire image. Structured light uses infrared lasers to project light with structural features onto the object being measured. The position captured by the camera varies depending on the distance. By calculating the offset between the captured light spot and a calibrated standard pattern at different locations, combined with parameters such as camera position and sensor size, the distance between the object and the camera can be determined . Both TOF and structured light are active ranging methods. Binocular vision is passive ranging, essentially a triangulation method that obtains depth information through the parallax between two cameras. The advantages of visual sensors are their wide detection range, rich information acquisition, and lower price compared to laser sensors. However, their disadvantages are their high computing power requirements. TOF is affected by multiple reflections, structured light is affected by glare, and binocular vision is affected by varying illumination and physical textures.

Figure 5

The above are the most common sensors, each with its own advantages and disadvantages. In practical applications, a combination of different sensors is generally used to maximize the ability of AGVs to accurately perceive obstacles in various applications and environmental conditions. As AGVs become increasingly intelligent, obstacle avoidance requirements are no longer as simple as parking. After sensors acquire obstacle information, obstacle avoidance algorithms can be used to update the target trajectory in real time and circumvent obstacles. Traditional obstacle avoidance algorithms include the Bug algorithm, the Potential Field Method (PFM ) , and the Vector Field Histogram (VFH ) . In addition, there are other intelligent obstacle avoidance technologies such as neural networks and fuzzy logic.